GSMI 和 麦格纳:合作创新 冲压未来

在当今竞争激烈的汽车制造行业中,创新和效率是关键。为了在市场上脱颖而出,汽车制造商需要依靠先进的技术和高效的生产工艺。在这个领域,GSMI(全球先进制造研究所)和麦格纳公司携手合作,共同设计了一系列革命性的冲压模具,为汽车行业带来了前所未有的效率和质量提升。

GSMI一直以来都是工业创新的领导者,他们的专业知识和先进技术为许多行业带来了突破性的进展。麦格纳公司作为汽车零部件制造领域的领军企业,一直致力于提供高品质、高性能的产品,并不断寻求创新的生产工艺来提高效率和降低成本。

这次合作为麦格纳带来了全新的冲压模具设计,从而实现了生产效率的巨大提升。GSMI的工程师们结合了最先进的材料科学和冲压工艺,设计了一系列精密的模具,使得麦格纳能够以更快的速度生产出更高质量的汽车零部件。

这些新的冲压模具不仅提高了生产效率,还降低了能源消耗和废料产生。通过优化设计和精密加工,模具的耐用性和稳定性得到了显著提升,从而延长了设备的使用寿命并减少了维护成本。这种可持续的生产方式符合当今社会对环保和资源节约的迫切需求,为麦格纳赢得了更多的认可和信任。

这次合作不仅仅是技术上的突破,更是两家企业之间合作精神和共同追求卓越的体现。GSMI和麦格纳的团队共同努力,克服了种种挑战,将创新的理念付诸实践,为汽车制造行业带来了新的里程碑。

在未来,我们期待着看到这种合作模式的进一步发展,以及更多基于技术和创新的成果。GSMI和麦格纳将继续携手合作,共同推动汽车制造业向前发展,为客户提供更优质的产品和服务,创造更美好的未来。

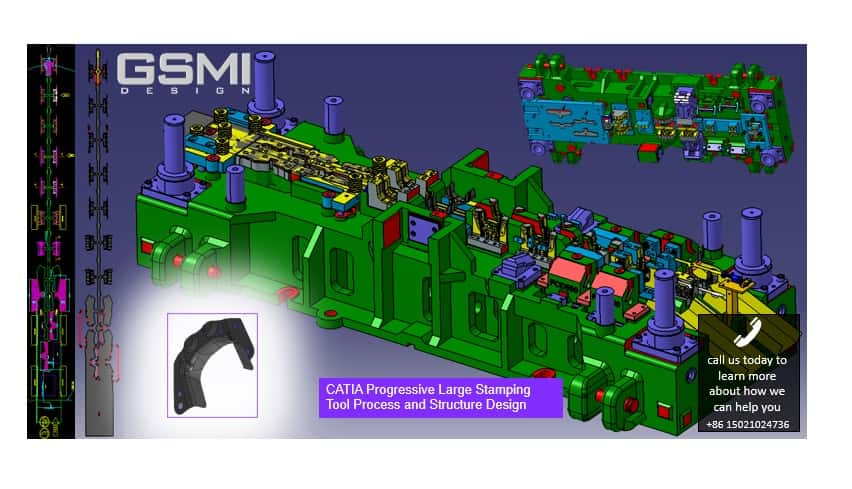

感谢麦格纳信任我们,让我们有机会为他们设计出真正出色的冲压模具。下图的刀具尺寸为4700*1700*1000。铸铁冲压渐进式工具的设计。

In today’s competitive automotive manufacturing industry, innovation and efficiency are key. In order to stand out in the marketplace, automakers need to rely on advanced technology and efficient production processes. In this arena, GSMI (Global Study Institute for Advanced Manufacturing) and Magna have teamed up to design a series of revolutionary stamping dies that have brought unprecedented efficiency and quality improvements to the automotive industry.

GSMI has long been a leader in industrial innovation, and their expertise and advanced technologies have led to breakthroughs in many industries. Magna, a leader in automotive parts manufacturing, is committed to delivering high-quality, high-performance products and continually seeks innovative production processes to improve efficiency and reduce costs.

This partnership has brought Magna a new stamping die design that has resulted in a huge increase in productivity. combining state-of-the-art material science and stamping processes, GSMI engineers have designed a series of precision dies that enable Magna to produce higher-quality automotive parts at a faster rate.

These new stamping dies not only increase productivity, but also reduce energy consumption and scrap generation. The durability and stability of the dies have been significantly improved through optimized design and precision machining, which extends the life of the equipment and reduces maintenance costs. This sustainable production method is in line with today’s urgent need for environmental protection and resource conservation, and has earned Magna more recognition and trust.

This partnership is more than a technological breakthrough, it is a demonstration of the spirit of cooperation and the shared pursuit of excellence between the two companies, as the GSMI and Magna teams have worked together to overcome challenges and put innovative ideas into practice, bringing new milestones to the automotive manufacturing industry.

In the future, we look forward to seeing the further development of this model of cooperation and more results based on technology and innovation. GSMI and Magna will continue to work together to drive the automotive manufacturing industry forward, provide customers with better products and services, and create a better future.

Thanks to Magna for trusting us with the opportunity to design a truly outstanding stamping tool for them. The tool size in the picture below is 470017001000. cast iron stamping progressive tool design.

为麦格纳设计的冲压模具